Additive Manufacturing

Rapid Prototyping & Validation

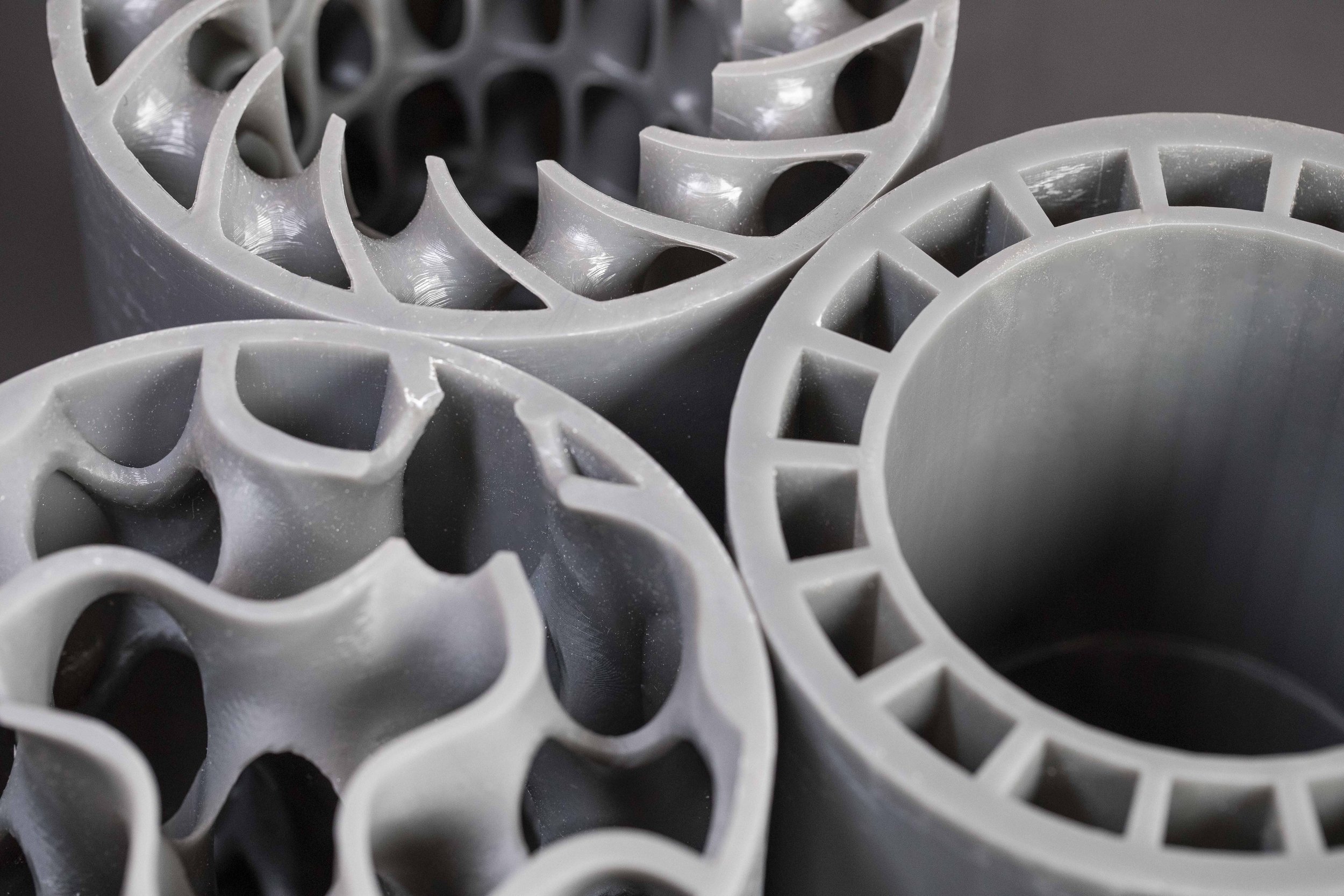

IS4S has a wide range of 3D printing capabilities, from rapid prototyping with stereolithography (SLA) printers by FormLabs all the way up to Fortus 450mc production using the fused deposition modeling (FDM) printer by Stratasys. We can not only rapidly develop products and ideas but also deliver quality production-level parts to our customers. Our team has expertise in both SolidWorks and Inventor which provide our customers options when developing mechanical systems and solutions.

We also use additive manufacturing (AM) approaches to validate enclosure designs and to dry-fit pieces and parts during the design phase of projects to minimize changes required during integration.

Munitions Additive Manufacturing

Rapid testing and development of new technologies is crucial to modern warfare’s evolving needs. Additive manufacturing enables these rapid technology advancements through modularity, eliminating retooling needs, and supporting scalable production. We have worked with AM experts to develop and test novel additive munitions such as a conformally printed electronic circuit for the 40mm grenade.

IS4S is also leading design, fabrication, delivery, and performance testing of first-of-its-kind full-scale AM munitions that provide double the performance, and we have delivered multiple full-scale additively manufactured warheads to the government and demonstrated performance improvements achievable only through AM-enabled technologies. These AM weapons were iteratively designed and simulated by IS4S using well-characterized high strength AM metals. Our unique combination of warhead design domain knowledge, digital engineering simulation capabilities, and application of cutting-edge AM technologies is leading to significant increases in munition capability.

Energetic 3D Printing

IS4S is at the edge of energetic 3D printing through the development of novel energetic filaments, testing additively manufactured explosives, and working safety designs for energetic printers.

Energetics have traditionally been manufactured through conventional methods such as pressing or casting. However, 3D printing has opened new possibilities in geometries that would be impossible with traditional methods. IS4S has developed specialty incendiary filaments that print from a typical FDM or SLS 3D printer. These filaments have been successfully fired from 12 gauge and 40mm platforms. In addition to the new filaments, we have designed printer modifications that enhance reliability and safety when processing energetics on commercially available printers.

Additive/Subtractive Manufacturing Center

IS4S has developed advanced manufacturing systems by utilizing cutting edge manufacturing technologies integrated into our custom shipping container solutions. These systems leverage current additive and subtractive manufacturing technologies to provide an agile and distributed solution. The system can be automated through robotic integration to provide maximum flexibility and capability.

With the advancement of distributed manufacturing solutions through systems like these, we are working to bring together innovative design with advanced manufacturing capabilities. This includes utilizing advanced manufacturing systems with AI and adaptive manufacturing capabilities to modernize weapon systems, enhance warfighter capabilities, and increase material readiness.

Let’s talk Additive Manufacturing.

We offer additive manufacturing solutions out of multiple office sites. Give us a little detail about your project needs and we’ll get you in touch with the best suited team.