Purposeful Problem Solving

Establishing our headquarters in Huntsville, Alabama was an intentional choice that keeps us connected to our military commitment and purpose every day. Following our model of planting offices to meet specialized needs, we quickly expanded to multiple locations in Huntsville with groups both off and on base at Redstone Arsenal.

Our Huntsville teams have deep technical knowledge in a broad spectrum of areas and a profound understanding of their work’s impact. This combination fosters an environment of perpetual mentorship, collaboration, and development of outside-the-box, multidisciplinary approaches to the complex challenges our customers face.

While our team members embody a diversity of skill sets, we are all united in our mission: to provide high-quality, innovative, integrated solutions for our nation’s warfighters and intelligence communities.

Integrated Solutions

-

AS9100 Certified Quality & Manufacturing

Flexible Manufacturing Space

Elastic Manufacturing Pioneers

Multiple Dedicated Facilities

-

Customer-Owned Technical Data Package (TDP)

Agile & Elastic Manufacturing

-

Software Services (Web Based Applications

Satellite Command & Control (C2) Ground Systems

-

Expeditionary Maintenance & Repair Container (EMARC) Systems

Gas & Water Generation Systems

Portable Shower Stations

Mobile Decontamination Systems

Portable Tool Storage

Electromagnetic Pulse Protection

-

J1939 Digital Architectures

Vehicle System Designs

Control Systems

Battery Management Systems

-

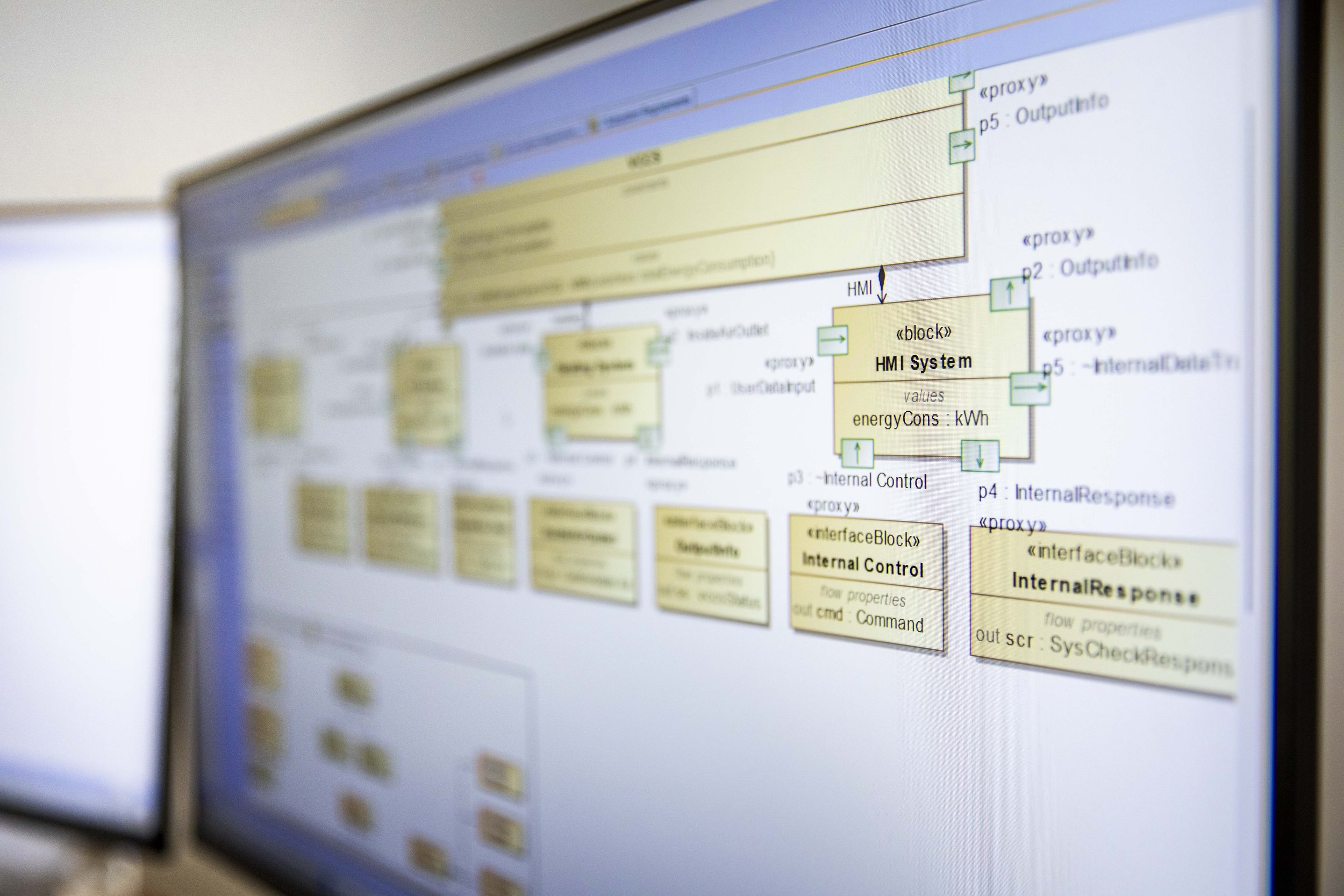

Systems Engineering (SE)

Model-Based Systems Engineering (MBSE)

Digital Engineering (DE)

Full Lifecycle

Requirements Tracking & Verification

Systems Architectures

Reference Architectures

System Modeling Language (SysML)

Digital Twin

Traceability

-

Model-Based Systems Engineering (MBSE)

Robot Operating System (ROS)

Weapons Open Systems Architectures (WOSA) Consortium Member

-

Embedded Systems

Agile

C/C++

Real-Time Operating Systems (RTOS)

Digital Twin

CI/CD

Full Stack

-

Circuit Board Assembly Design

Line Replaceable Unit (LRU) Design, Integration, & Testing

Custom Radio Frequency (RF) Designs

Custom Printed Circuit Board (PCB) Integration

Commercial-Off-The-Shelf (COTS) Electronics Integrations

Low Size Weight and Power (SWaP)

-

Validate Form & Fit

Rapid Prototyping: Polymer, Metal & Carbon Fiber Infused Printers

-

Inflatable

Container Based

Backpack

-

Modeling & Simulation

Custom Signal Design

Software Defined Radio

Weapon Datalinks

Line of Site, Satellite, & Last Mile Connectivity

-

Software Defined Radio

Radio Frequency (RF) Signal Processing

Non-RF Sensor Integration

Signal Encryption

Assured PNT

Navigation Warfare

Anti-Jam

Integrity

Satellite Signal Design

Global Navigation Satellite System (GNSS) Signal Processing

Advanced Receiver Architectures

Precision Timing Integration

-

Artificial Intelligence (AI) / Machine Learning (ML) In Real World Robotics Solutions

Autonomous Tracked Vehicles

Controller Area Network (CAN)

Robot Operating System (ROS)

Custom Applications

-

Propulsion Systems

Power Generation

Electronic Controls

Offensive Launchers

Air Defense Launchers

Our Work

Our Products

Integrated Container Solutions

Integrated Container Solutions (ICS) is a wholly owned subsidiary of IS4S that designs and builds customized ISO shipping containers configured with specially integrated equipment to provide portable services in austere environments. Additionally, ICS provides decontamination systems, power generation systems, nitrogen, oxygen and water generation systems, and a wide variety of housing, kitchen, and other solutions.

To find out how ICS can create a custom build for you, visit IntegratedContainerSolutions.com or email us at containers@is4s.com.

Aircraft & Vehicle Survivability Barrier

The aircraft and vehicle survivability barrier is used to prevent aircraft and ground vehicle contamination when transporting contaminated or infected personnel. We have multiple versions of the survivability barrier with options for aircraft and ground vehicles of various sizes.

Contact us for more information on options and how the survivability barrier can help your team.

Huntsville Leadership

Robert Henderson

Executive Vice President

Wendy Bustios

Vice President

-

Wendy Bustios has over 21 years of experience working with both government and commercial sectors. Her journey began at a local CPA firm where she worked with a variety of clientele, including IS4S, and cemented her role as an asset to the IS4S team. Wendy’s knowledge includes Federal Acquisition Regulation (FAR), Defense Contract Audit Agency (DCAA), incurred cost submissions, compliance, financial statement preparation, cost accounting system set up and reviews, and policy and procedure preparation.

Wendy serves as a trusted advisor to senior managers. Her expert management of payroll, accounts payable, and various taxes, such as payroll, corporate, and use, is indispensable to corporate leadership. Wendy ensures IS4S is always prepared for various audits, including 401K, worker’s compensation, DCAA accounting system, voucher, and incurred cost submission. In addition, her knowledge in identifying filing and registration requirements for IS4S’s multi-state operations help minimize state tax liabilities.

Wendy currently serves as a vice president of operations and oversees the accounting department.

Luke Edwards

Associate Vice President

-

Luke Edwards has been with IS4S since 2010, and he currently serves as an associate vice president and site lead. His work focuses on software defined global navigation satellite system (GNSS) receiver design, radio frequency (RF) communications systems, digital signal processing, control system design, field-programmable gate array (FPGA) development, and real-time embedded systems. Luke has led efforts for multiple customers that use the vector tracking receiver (VTRx), a highly configurable software defined radio for PNT systems.

Before this, he was the modeling and control systems lead for four artillery vehicles on Redstone Arsenal, developing real-time control systems for turret motion using hydraulic and electric drive systems. Luke received his master's degree from Auburn University where he served as a research assistant in the GPS and Vehicle Dynamics Laboratory (GAVLAB) specializing in software defined radios for GNSS systems and advanced signal processing techniques using FPGAs.

Matt Anderson

Senior Technical Fellow

-

Matt Anderson has over 15 years of experience in the design and implementation of electronic circuits and embedded systems, including developing and integrating cutting-edge technology across diverse platforms. Since joining IS4S over 12 years ago, Matt has played a pivotal role in creating end-to-end engineering solutions, from printed circuit board (PCB) design and embedded firmware to advanced robotics systems.

Matt specializes in PCB design, embedded firmware/VHDL development, and software architecture, and has developed advanced embedded process control systems and delivered solutions for projects involving highly specialized electronics. His expertise includes designing and optimizing turbine engine controllers for reliable, high-performance operation in challenging environments.

In addition, Matt has led the development of robotics systems, integrating cutting-edge vision systems, advanced navigation algorithms, and Simultaneous Localization and Mapping (SLAM) technologies. His contributions to micro-electromechanical systems (MEMS) support electronics ensure precision and reliability in micro-scale sensors and actuators.

With a proven track record of innovation and quality, Matt continues to push the boundaries of electronics and software engineering, delivering comprehensive solutions to meet the evolving needs of modern technology.

Charles DePlachett

Senior Technical Fellow

-

Charles DePlachett has served over 30 years in both government and commercial sectors. Early in his career, Charles spent over 10 years developing engineering software tools including gas turbine engine cycle analysis, data acquisition and control systems, space telescope structural and optical analysis, and fiber optic thermal imaging. During this time, he developed the Graphical Engine Cycle Analysis Tool (GECAT) software, a pre- and post-processor for the NASA Engine Performance Program (NEPP) for gas turbine engine cycle analysis.

Charles worked several years at the US Army Aviation and Missile Research, Development and Engineering Center (AMRDEC), developing data acquisition and control systems and supporting testing of solid rocket motors, small internal combustion engines and gas turbine engines for missiles and UAVs. He returned to the commercial sector to lead propulsion efforts for the AMRDEC NLOS-T demonstration vehicle and subsequently developed the Propeller Wizard design and analysis tool for propeller performance and noise prediction. More recently, Charles has been involved in developing and integrating small propulsion and power systems for smoke obscuration systems, UAVs, and missiles. He has led the development of several engine control unit (ECU) modules for small gas turbine engines.

Charles is a licensed PE in the state of Alabama with a master’s degree in mechanical engineering with emphasis in propulsion and control systems. He has been with IS4S since February 2010.

Charles oversees Huntsville quality and was instrumental in the Huntsville facility achieving ISO 9001 certification in 2018 and AS9100 certification in 2022 and remains steadily involved in manufacturing planning and management.

Huntsville Careers

Join us in our mission to solve complex problems of national importance in an environment where doing the right thing is more important than profit, and in a company fully owned and operated by ethical, motivated employees.

Check out our active job openings to apply!

Contact Us

Huntsville Site Addresses

HEADQUARTERS

308 Voyager Way NW

Suite 200

Huntsville, AL 35806

CAGE: 4ZJX8

PRODUCTION SITE

822 James Record Rd SW

Suite F

Huntsville, AL 35824

OFFICE SITE

2995 Wall Triana Hwy SW

Suite A1

Huntsville, AL 35824

We are AS9100 certified by NSF-ISR at our Huntsville James Record Rd and Wall Triana Hwy sites.