Systems Engineering & Integration

SE, DE, & MBSE

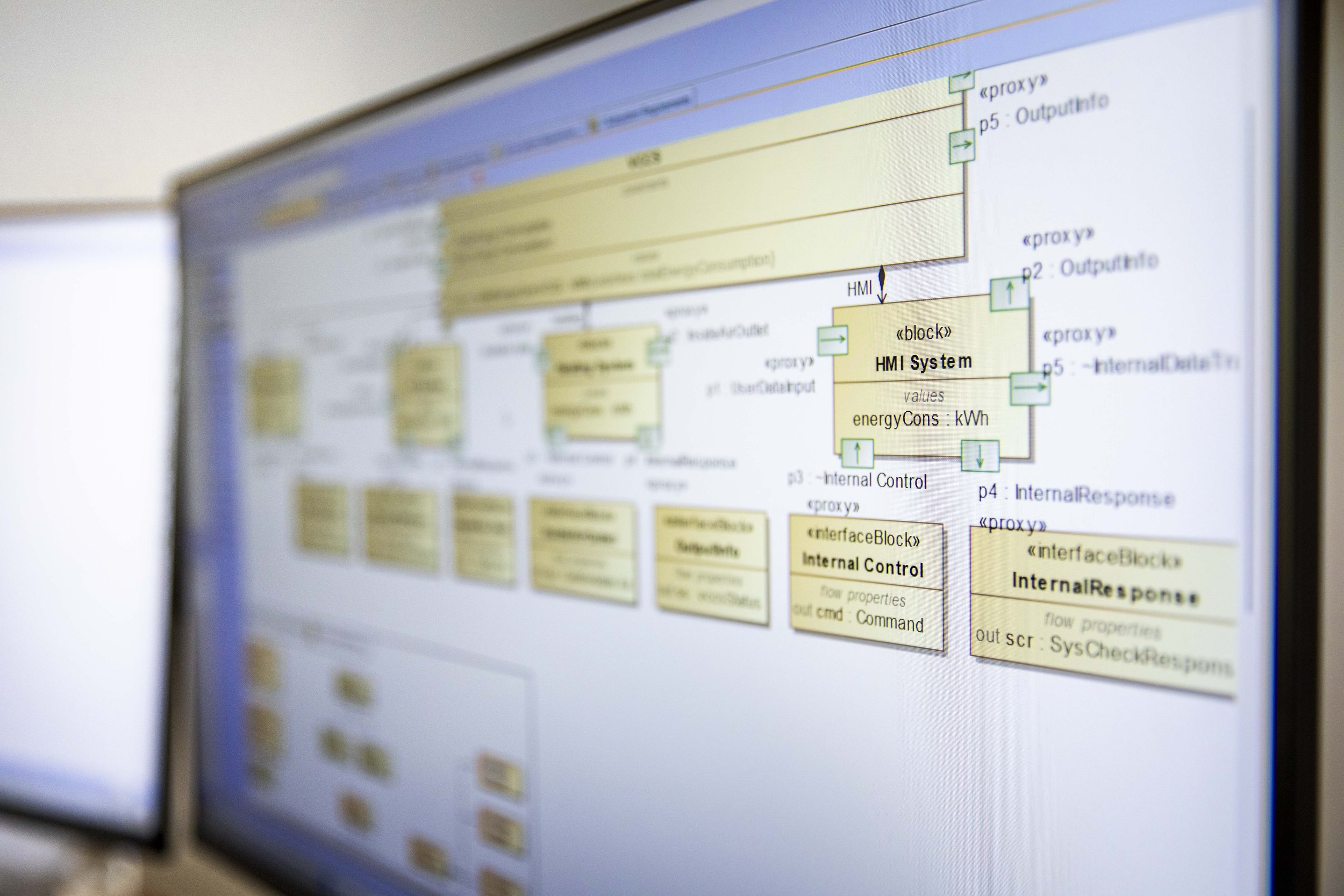

IS4S combines traditional systems engineering (SE) with cutting-edge digital engineering (DE) to drive innovation through model-based systems engineering (MBSE). Using Cameo Systems Modeler, we create digital twins of products, ensuring thorough requirements traceability and accountability. Throughout the design lifecycle, systems engineering is embedded to enhance programmatic and technical performance. Dynamic information is continuously tracked using system modeling language (SysML) software, enabling real-time optimization of complex systems. This approach streamlines development, improves efficiency, and fosters the delivery of high-quality, reliable products.

Model-Based Systems Engineering (MBSE)

The IS4S systems engineering team develop system and software architecture models using a standard government-adopted MBSE tool and an object-oriented approach to complex system design. This team has developed custom and easily adopted processes for rapidly capturing functionality and bill of materials (BOM)-like structure and digitally relating those data elements to the system design, allowing the support engineering teams to implement safety, cybersecurity, and program management detail into the MBSE model. With our customer-centric approach, the intention is to create a robust and enduring model product that is easily accessible by the layman while staying extensible to future digital engineering integration.

Systems Engineering Standards

Our team includes several senior systems engineers with extensive government and industry experience leveraging systems engineering principles. We adhere to the guidelines set forth in the International Council of Systems Engineering (INCOSE), and we follow an object-oriented systems engineering methodology (OOSEM) for our digital engineering efforts.

MBSE for Cruise Missile

Given mission parameters (range, cruise speed, cruise altitude, etc.) and initial estimates of aerodynamic properties, the system simulation model iterates to optimize the design. Each block contains an underlying analytical model of the components’ performance characteristics. Examples include wing loading, thrust-to-weight ratio, required power and energy, and design geometry. Outputs are linked to a computer-aided design (CAD) model which is linked to a high-fidelity computational fluid dynamics (CFD) model. The refined system parameters and performance data are then integrated back into MBSE tools to update system requirements, inform trade studies, and validate architecture decisions.

MBSE Warhead Development

We utilize MBSE while developing warheads, and the decisions made in the design process are also captured through MBSE. We have developed a warhead from the ground-up with systems engineering, program management, and contracting requirements all delivered in a single model, while other models involve development concurrently with design and manufacturing efforts, and others are developed as digital twins for future flight vehicle integration.

Nuclear Safety / AFMAN-119 Software Systems Engineering

Our experience in reverse-engineering large OEM software, completing development of that software, testing, and integrating is a rare combination as the United States looks to modernize its strategic arsenal. Our expertise has been applied to develop software in support of AFMAN 119 requirements, which represent some of the most critical functions for ensuring human intent is executed in a safe and effective manner for our nation's most challenging strategic problems.

Weapon System Integration Into Aerial Platforms

Our approach to executing the Air Force integration program is deeply rooted in systems engineering principles, ensuring a structured and methodical framework for development and implementation. We utilize a comprehensive lifecycle approach that encompasses requirements analysis, design, implementation, testing, and validation. By leveraging MBSE, we create detailed simulations and prototypes that facilitate early detection of issues and enable iterative improvements. Our cross-functional teams collaborate closely to integrate various system components seamlessly, ensuring that all systems work together effectively to meet mission objectives.

Through rigorous risk management and performance assessment, we ensure that the integration process aligns with operational requirements and enhances overall capability, readiness, and efficiency within the Air Force.

Let’s talk Systems Engineering & Integration.

We offer systems engineering & integration solutions out of multiple office sites. Give us a little detail about your project needs and we’ll get you in touch with the best suited team.